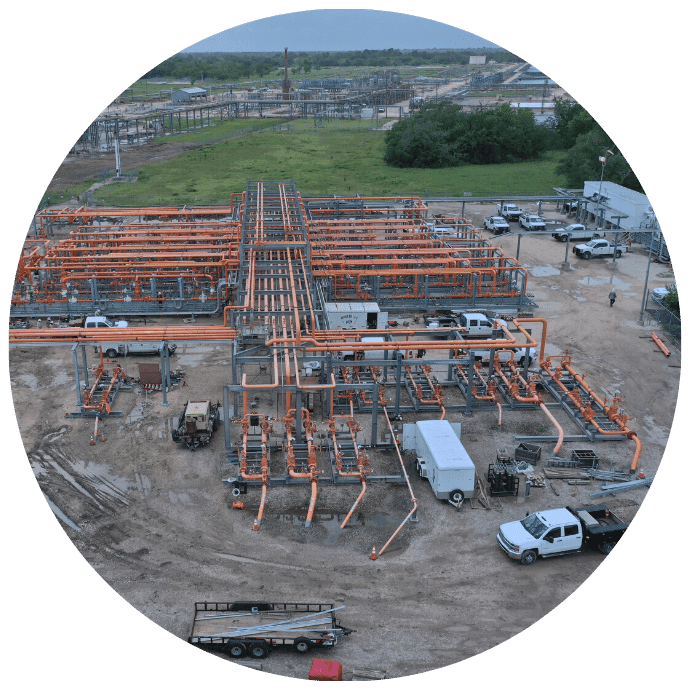

Brownfield Pipeline Facility Construction

Duphil’s experienced team works with other companies, landowners, and project managers while following all guidelines to ensure the successful completion of every brownfield pipeline facility station construction project. We have the manpower, resources, equipment and experience necessary to fulfill all your project needs.

Skid Mounted Equipment

Facility Upgrades

Facility Piping Modifications

Skid Mounted Equipment

Skid Mounted Equipment provides pipeline companies the opportunity to install new capabilities to their pipeline facilities without significant modification to the existing infrastructure. Duphil’s unique abilities as a contractor include installing regulator skids, fuel gas skids, and meter skids. Given the brownfield construction sites are often limited on space, planning begins well in advance for projects of this type. When preparing a site for construction, Duphil strategically locates all storage and staging areas so that they can most efficiently install the necessary additions. This ultimately leads to safe, timely project completion needed to satisfy our client’s objectives.

Facility Upgrades

As pipeline systems expand, facility upgrades are often needed to accommodate greater volumes or address operational inefficiencies that arise out of the expansion or modifications of the system. In order to support our clients, Duphil has developed expertise in the installation of filter separators, slug catchers, condensate tanks, and dehi units to ensure their pipeline systems remain operational and without incident. Given how vital these facility upgrades are to pipeline system reliability, Duphil plays a crucial role in supporting our client’s needs by working to complete high-quality, safely executed projects.

Facility Upgrades

As pipeline systems expand, facility upgrades are often needed to accommodate greater volumes or address operational inefficiencies that arise out of the expansion or modifications of the system. In order to support our clients, Duphil has developed expertise in the installation of filter separators, slug catchers, condensate tanks, and dehi units to ensure their pipeline systems remain operational and without incident. Given how vital these facility upgrades are to pipeline system reliability, Duphil plays a crucial role in supporting our client’s needs by working to complete high-quality, safely executed projects.

Facility Piping Modifications

Often times, pipeline facilities require modifications in order to capitalize on commercial opportunities or provide operational flexibility. As these modifications become needed, Duphil’s experienced personnel has the ability to work with our clients to create solutions related to MLV modifications, pipe rack installation/modification, in ground piping modifications, and necessary facility tie-ins. Duphil’s comprehensive team of professionals is ready to work with our clients to support them in their opportunities and needs.

Why Choose Duphil for Your Brownfield Pipeline Facility Construction

Brownfield Pipeline facility station construction requires an experienced, professional, and efficient team. Duphil has the expertise required to help you reach all your project goals both on time and on budget.

We understand the importance of engineering each station to meet all of your project needs. Our project managers have put in over eight million man hours over the past ten years to complete numerous pipeline facility construction projects successfully. From the initial planning stages to construction, reclamation, and everything in between, our highly trained crews will ensure that your pipeline is safe, in compliance, and meets all regulations.

Diversity of services under one roof

Quality work, total client satisfaction, and seamless project execution

Commitment to safeguarding our employees, clients, the public, and the environment

Vast resources, equipment, and personnel

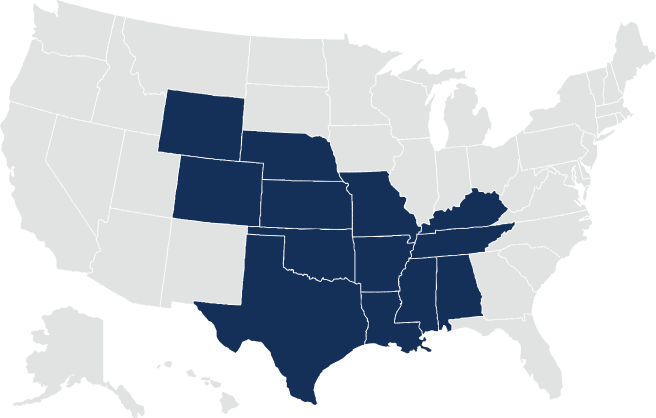

Expansive geographical coverage, with operations in 13 states

Contact Us

Fill out the form below or call us at 409-883-8550 to request more information.